Executive Summary

The prevailing fallacy in the United States home coffee market remains the “Boiler Bias”—the tendency for consumers to allocate 70-80% of their budget to the espresso machine while relegating the grinder to an afterthought. This is a fundamental error in resource allocation.

In 2026, the thermal stability of even entry-level PID-controlled machines has plateaued at a high standard. The variable limiting your cup quality is no longer temperature stability; it is particle consistency. The espresso machine acts merely as a solvent delivery system; the grinder creates the surface area that determines the chemical reaction.

This analysis dissects the physics of extraction, addresses the 2026 standards for workflow hygiene, and evaluates the current top-tier options for the US prosumer market.

The Science of Extraction (The “Why”)

To understand why a $400 grinder often outperforms a $2,000 machine setup, one must understand the physics occurring inside the portafilter basket. We are not making a hot beverage; we are executing a pressurized chemical solvent extraction.

Particle Size Distribution (PSD)

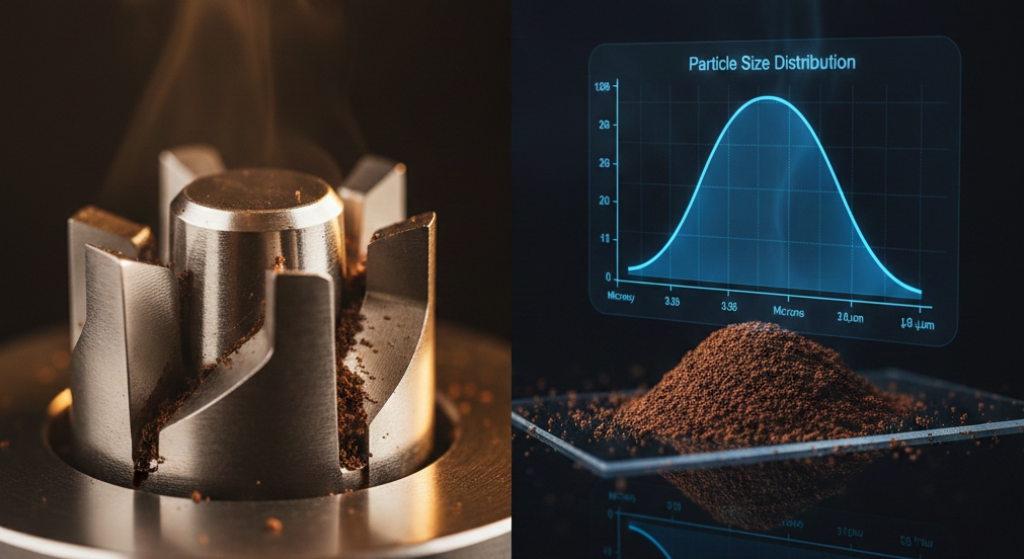

No grinder produces particles of identical size. Instead, every grinder produces a spectrum of particle sizes, plotted on a curve known as the Particle Size Distribution (PSD).

In 2026, the analysis of PSD generally categorizes output into two distinct profiles:

1. Monomodal (Unimodal) Distribution: Ideally, this presents a single, narrow peak on the graph. The particles are highly uniform. This distribution creates a puck with uniform resistance, allowing water to flow evenly. This is the “Holy Grail” for light-roast aficionados seeking high extraction yields (22%+) and flavor clarity.

2. Bimodal Distribution: This curve features two peaks. One peak represents the target grind size, and a secondary peak represents a deliberate inclusion of “fines.” This is traditional for medium-to-dark roasts. The fines migrate to the bottom of the basket, restricting flow and creating the resistance necessary for 9-bar pressure, resulting in heavy body and texture.

The Physics of Channeling

The enemy of extraction is the “Path of Least Resistance.” Water under pressure (9 bars = ~130 PSI) is lazy; it will always find the easiest route through the coffee puck.

Inexpensive grinders produce an uncontrolled, chaotic PSD. They generate excessive **fines** (dust-like particles <100 microns) and boulders (large chunks >600 microns) simultaneously.

The Fines: Clog the filter basket holes, choking the flow.

The Boulders: Create pockets of low resistance.

When flow is choked by fines, pressure builds until the water forces a breach through the area surrounding a boulder. This is channeling.

The result is a sensory paradox: The fines over-extract (releasing tannins/bitterness), while the boulders inside the channel under-extract (releasing sour acids). The resulting shot is simultaneously bitter and sour—a flaw no amount of PID temperature control on your machine can fix.

Burr Geometry: Flat vs. Conical

The hardware debate in 2026 continues to center on the physical geometry of the crushing mechanism.

Conical Burrs: The traditional choice (e.g., Baratza tech). Gravity feeds beans into a rotating cone inside a stationary ring.

The Physics: Conicals naturally produce a Bimodal PSD. They create more fines, which helps seal the puck.

Sensory Profile: High texture, thick mouthfeel, forgiving workflow. Ideal for traditional espresso blends.

Flat Burrs: The 2026 Enthusiast Standard (e.g., DF64, Fellow). Two horizontal rings spin against each other, using centrifugal force to eject grounds.

The Physics: When aligned correctly, flat burrs produce a Unimodal-leaning PSD.

Sensory Profile: High flavor separation, clarity, and acidity. They expose the nuance of single-origin beans but are less forgiving of poor puck prep.

The 2026 Workflow Problems: Static & Retention

In the current market, grind quality is the baseline. The differentiator between a good product and a great one is workflow hygiene. US consumers have largely rejected the “hopper-based” workflow in favor of **Single Dosing** (weighing beans per cup), necessitating new technical solutions.

The Static Enemy

Coffee grinding involves high-friction crushing of organic material, generating significant electrostatic charge. In arid US climates (or winter heating), this causes grounds to cling to the exit chute and the catch cup. This “chaff” creates a mess and alters the ratio of coffee in the basket.

The Manual Fix: RDT (Ross Droplet Technique)

For years, enthusiasts have used RDT—adding a single drop of water to the beans before grinding. This increases surface conductivity, allowing the static charge to dissipate. While effective, it introduces moisture to the burr chamber, raising long-term concerns regarding oxidation and corrosion in non-stainless steel burrs.

Plasma Generators / Ionizers

The most significant tech adoption in 2024-2026 has been the integration of Plasma Generators (or Ionizers) into the exit chutes of consumer grinders. This technology, previously reserved for industrial manufacturing, actively emits negative ions into the grind path.

These ions neutralize the positive static charge generated by friction. The result is a fluffy mound of coffee that falls vertically without clinging to the chute. In 2026, a grinder lacking an ionizer is technically obsolete for the single-dosing market.

Defining “Zero Retention”

Retention is the silent killer of flavor. It refers to the amount of coffee retained inside the grinder after the motor stops.

Exchange Retention: If a grinder creates 18g of output from 18g of input, it may still have “exchanged” 1g of old, stale coffee stuck in the chamber for 1g of fresh coffee.

The Standard: A true “Zero Retention” grinder (typically <0.1g variance) ensures that what you brew is exactly what you just ground, without cross-contamination from yesterday’s roast. This is achieved through vertical mounting, bellows, and minimized dead space.

The Top 3 US Grinders for 2026 (Analyst Comparison)

We have isolated three models that dominate the US market segments. These are evaluated not on marketing claims, but on torque, alignment, and grind distribution analysis.

Model A: Baratza Encore ESP

Price Point: ~$199

Category: Entry-Level Prosumer

The Target User: The traditionalist or beginner upgrading from a blade grinder or pre-ground coffee. They value support over experimental features.

Technical Pros:

The M2 Burr Set: Baratza utilizes the M2 conical burr (previously an upgrade for the standard Encore). It provides a sharp cut with a forgiving bimodal distribution, excellent for medium-dark roasts.

Dual-Range Adjustment: The “ESP” gearing allows for micro-adjustments in the espresso range while maintaining macro-steps for filter coffee.

Repairability: Best-in-class parts availability.

Workflow Cons:

Noise Pollution: The DC motor and gearbox assembly generate significant decibels compared to belt-driven rivals.

Retention: Lacks a bellows or ionizer. Requires “percussive maintenance” (tapping the lid) to dislodge the final 0.5g-1.0g of coffee.

Analyst Verdict: The utilitarian workhorse. It lacks refinement, but its particle quality per dollar is difficult to beat for traditional espresso profiles.

Model B: Fellow Opus

Price Point: ~$195

Category: The Aesthetic All-Rounder

The Target User: The design-forward user who brews both espresso and cold brew, often with limited counter space.

Technical Pros:

High-Torque Motor: Operates at 6 Newton-meters (Nm) of torque. This is critical for preventing stalls when grinding light, dense roasts at fine settings—a common failure point in sub-$200 grinders.

C6-40 Burly Burrs: A unique 6-blade conical design that produces a surprisingly complex cup profile.

Workflow Cons:

The User Interface (UI): The adjustment mechanism is technically flawed. It relies on an outer ring for macro steps and an inner ring for micro steps, requiring mental math to dial in specific settings. It is non-intuitive.

Retention: Despite the “anti-static” claims, retention is noticeable. The lid doubles as a bellows, but the workflow feels clunky.

Analyst Verdict: Excellent internal engineering hampered by over-designed external controls. Buy it for the torque and the look; tolerate the dial.

Model C: DF64 Gen 2

Price Point: ~$399

Category: The Enthusiast Benchmark

The Target User: The data-driven home barista seeking high extraction yields and the ability to modify hardware.

Technical Pros:

64mm Flat Burrs: This is the industry standard diameter. It allows the user to swap stock burrs for premium SSP options (High-Uniformity or Multipurpose) later, changing the grinder’s entire flavor profile.

Plasma Generator: The Gen 2 integration of the ionizer completely solved the mess issues of the Gen 1, making RDT largely unnecessary.

Speed: fast grind times due to large burr surface area.

Workflow Cons:

Build Quality: While sturdy, the finishing lacks the polish of Fellow or Baratza. It feels industrial.

Power Button: oddly placed, requiring a reach-around or awkward finger placement.

Analyst Verdict: The price-to-performance leader. It offers the output quality of $1,000+ commercial grinders from five years ago. It is the only option on this list for true “light roast” clarity.

The “Serviceability Index” (Why Buy US?)

In an era of drop-shipped appliances from anonymous overseas factories, the **Serviceability Index** is a critical metric for 2026. Coffee grinders are mechanical devices subject to high torque, heat, and wear. They *will* require maintenance.

The “Right to Repair”: Brands like Baratza (acquired by Breville but maintained separate ops) and Fellow maintain US-based headquarters. This ensures that when a plastic gear shears or a belt snaps in year three, you can purchase a specific SKU replacement part rather than landfilling the unit.

Import Risks: Purchasing “white label” grinders direct from overseas marketplaces often results in a “zero-support” scenario. If the control board fails, the unit is bricked.

Analyst Recommendation: Always factor the availability of replacement burrs and motors into the Total Cost of Ownership (TCO). A $400 grinder that lasts 10 years is cheaper than a $200 grinder that lasts two.

Conclusion

The hierarchy of espresso equipment is immutable: Beans > Grinder > Water > Barista > Machine.

If you are currently using a machine with a commercial 58mm portafilter and a PID controller, but you are pairing it with a budget grinder, you are strictly limited by the particle size distribution of that grinder. You are likely compensating for bad physics—dosing up to hide channeling or grinding coarser to avoid clogging—rather than dialing in flavor.

The Analyst’s Advice: Date the machine, marry the grinder. Machines are technology that updates every few years with new displays and warm-up times. A grinder with good alignment, a powerful motor, and high-quality burrs is a long-term partner that defines the ceiling of your coffee quality.

Call to Action: Before you upgrade your espresso machine in 2026, audit your grinder. If you are experiencing sour/bitter confusion or inconsistent shot times, the fault lies in your PSD, not your boiler pressure.

Comparison Summary Table

| Feature | Baratza Encore ESP | Fellow Opus | DF64 Gen 2 |

| Price (USD) | $199 | $195 | $399 |

| Burr Type | 40mm Conical (M2) | 40mm Conical (C6-40) | 64mm Flat (Stainless) |

| Flavor Profile | High Body, Blended | Balanced, Sweet | High Clarity, Separation |

| PSD Profile | Bimodal | Bimodal | Unimodal-Leaning |

| Static Tech | None (Passive) | Anti-Static Tech (Weak) | Plasma Generator |

| Retention | Medium (Needs Tapping) | Low-Medium (Lid Pump) | Near Zero |

| Upgrade Path | Low (Proprietary) | Low (Proprietary) | High (SSP Compatible) |

| Analyst Verdict | Best for Reliability | Best for Aesthetics | Best for Performance |